Fast Production

Complete each production batch within 20 minutes for efficient, energy-saving, and rapid production, contrasting with the conventional 2-hour minimum time requirements.

Smart Production

Our automated system precisely controls the urea-water mixture, continuously adjusting component percentages in real-time. This ensures efficient and dynamic production processes without wasted batches.

Low Energy Consumption

The innovative cold blending technology minimizes the need for water heating during urea dissolution, significantly reducing energy usage. This efficient process ensures optimal production performance while lowering operational costs.

PROFITABLE – FAST – SMART

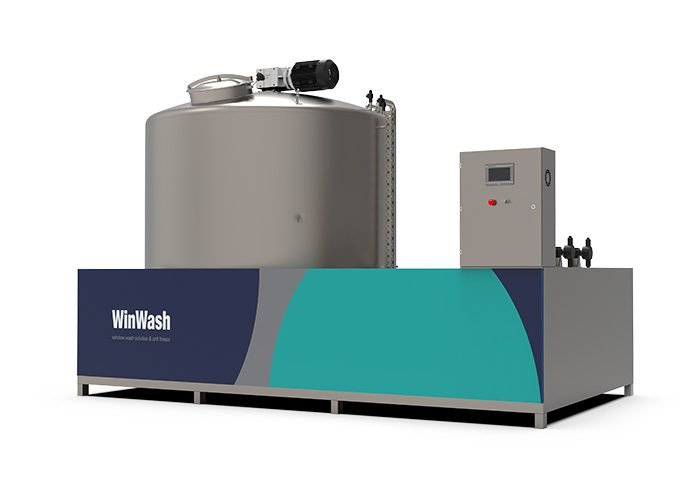

State-of-the-Art WinWash, Coolant & Anti Freeze Production Plant

Compatible with Euro Standards

Our advanced production systems are engineered for efficient and economical manufacturing of high-quality window washing solutions and antifreeze products. Designed to meet diverse climate demands, our plants support standard formulations for -60°C, -30°C, and seasonal conditions, with options for custom blends upon request.